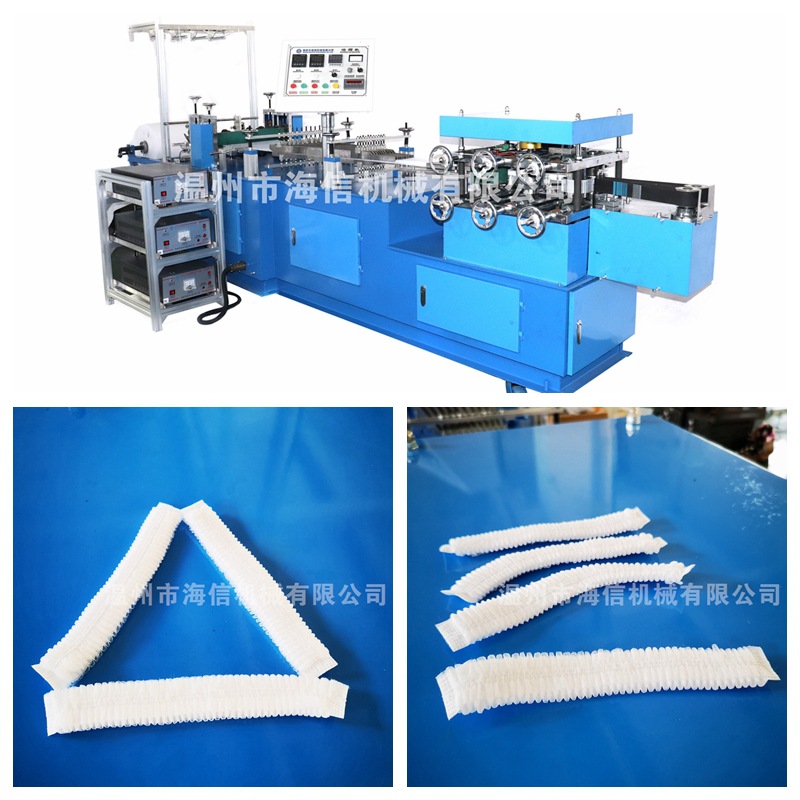

全自動無紡布浴帽機-PE塑料條形帽子機-無紡布條帽機

價格

訂貨量(臺)

¥51800.00

≥1

店鋪主推品 熱銷潛力款

萦萧萨萪萪萬萩萬萩萪萩

在線客服

性能及特點:

性能及特點:

Performance and features:

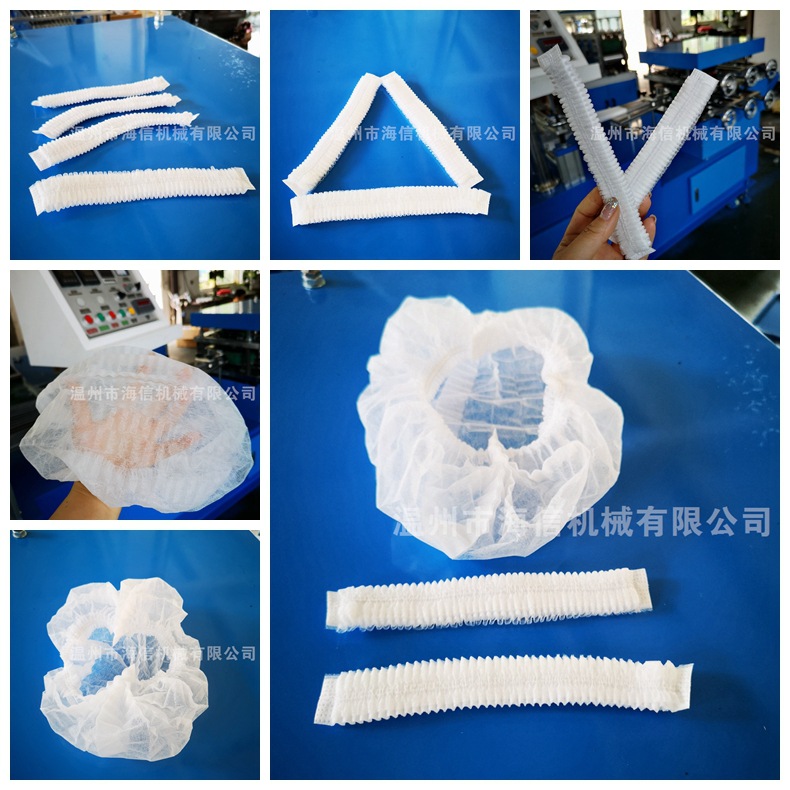

1.本機可以生產無紡布材料和塑料薄膜材料的一次性防塵無紡布條形帽,本機具有質量好,價格低,產量高等優點,節約人工,降低成本,可以根據客戶的要求訂做。

1. This machine can produce disposable dust-proof non-woven strip caps of non-woven materials and plastic film materials. This machine has the advantages of good quality, low price and high output, saving labor and reducing costs, which can be based on customer requirements. Custom made.

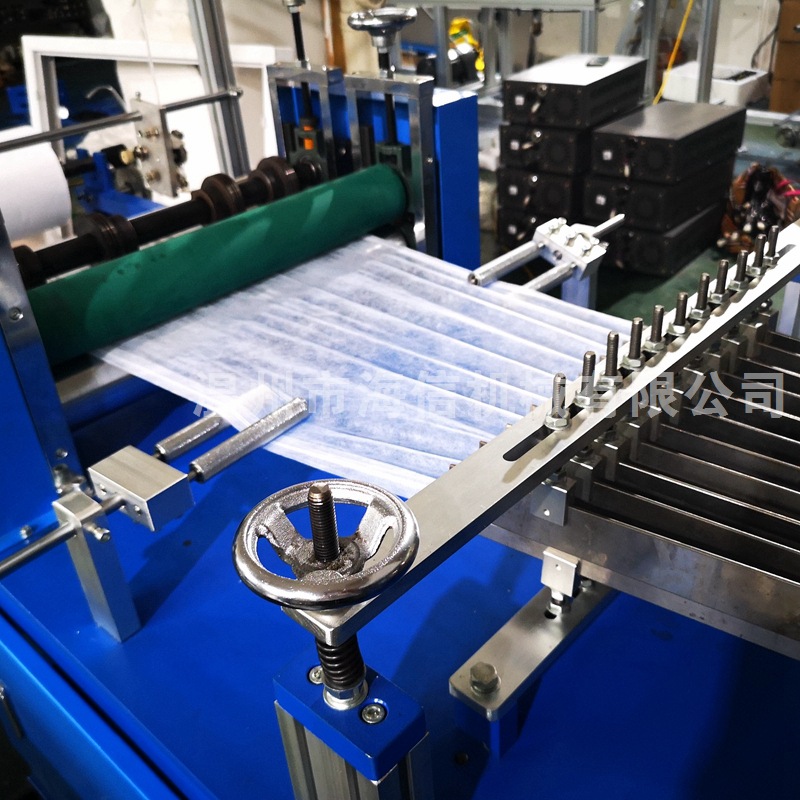

2.本機臺為自動化。從原料送入至層品到產品計數全程自動化作業。采用超大功率超聲波焊接,將無紡布的兩端及橡筋有效固定。從原料送入到成品全程自動化作,電腦無極調速運轉更靈活,全程只需一個工作人員。

2.The machine is automated. Automated operations from raw material feed to laminate to product count. Ultra-high power ultrasonic welding is used to effectively fix both ends of the non-woven fabric and the elastic band. From the raw material feeding to the finished product, the whole process is automated, and the computer stepless speed regulation operation is more flexible, and only one staff member is needed for the whole process.

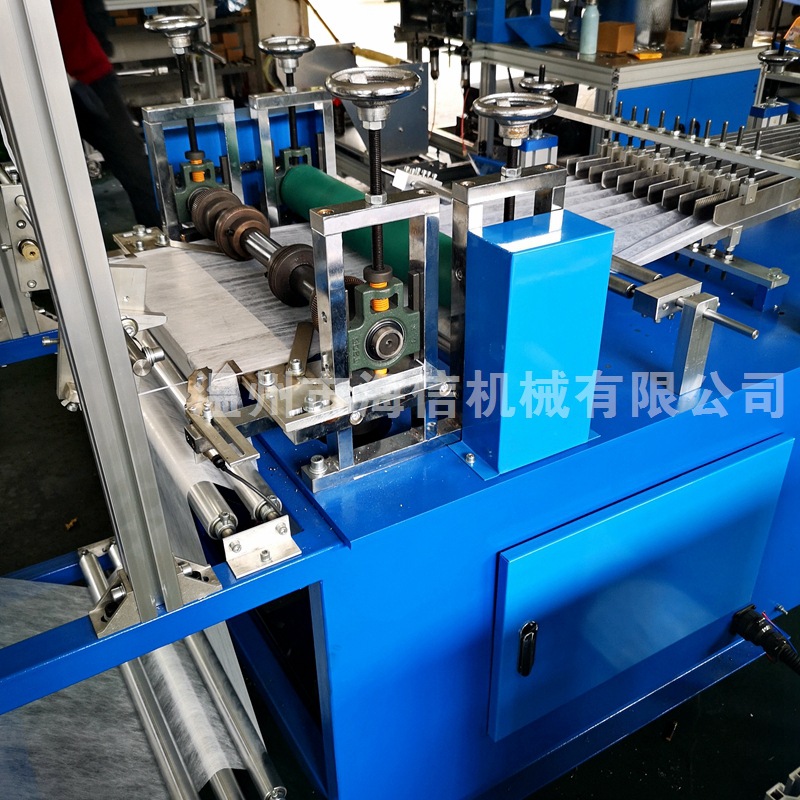

3.變頻控制調速。

3. Variable frequency control speed regulation.

4.一次性直接出成品。

4. Directly out of the finished product at one time.

5.自動恒溫控制。

5. Automatic constant temperature control.

6.超聲波熔焊與電熱合相結合,使產品更加的舒適、牢固。

6.Ultrasonic welding combined with electric heating to make the product more comfortable and firm.

7. 主要部件采用鋁件使機器更輕更光潔。

7. The main components are made of aluminum to make the machine lighter and smoother.

設備工藝:

設備采用超聲波熱合方式,變頻調速,生產無紡布材料和塑料薄膜材料一次性防塵無紡布條形帽從送料到成品完成一體化生產。

Equipment process:

The equipment adopts ultrasonic heat sealing method, frequency conversion speed regulation, and produces non-woven materials and plastic film materials. The disposable dust-proof non-woven strip caps are integrated into the finished product from feeding to finished products.

生產流程:

自動化送料—導入—折疊—焊接—成型切斷

Production Process:

Automated feeding - introduction - folding - welding - forming cut

兩種選擇:

我們這款機器可以生產兩種款式的,一種是鐵架,一種是鋁架的。(可選配PLC觸摸屏)

Two options:

Our machine can produce two styles, one is iron frame and the other is aluminum frame. (Optional with PLC touch screen)

采購數量不能為空

聯系信息不能為空

驗證碼不正確